As we move further in 2021, the construction industry in the US continues to grow with leap and bounds. After the recession, the construction projects that were on hold have now accelerated their progress.

The construction industry works mainly on three pillars: materials availability, skilled workforce, and foundation construction equipment.

The construction industry has an addition to its overall workforce in the past quarter and the materials have shown an uptick in supply.

When we talk about construction equipment, pile driving equipment is always in demand for mining and construction projects. The pile driving equipment needs to be selected as per the job.

However, the question is what is pile-driving equipment?

Pile Driving Equipment

A pile driving equipment is used to drive or extract piles into the ground or soil. They are effective in digging holes in the soil.

There is a wide range of pile driving equipment available as per different kind of projects:

Vibratory Hammers

Diesel Hammers

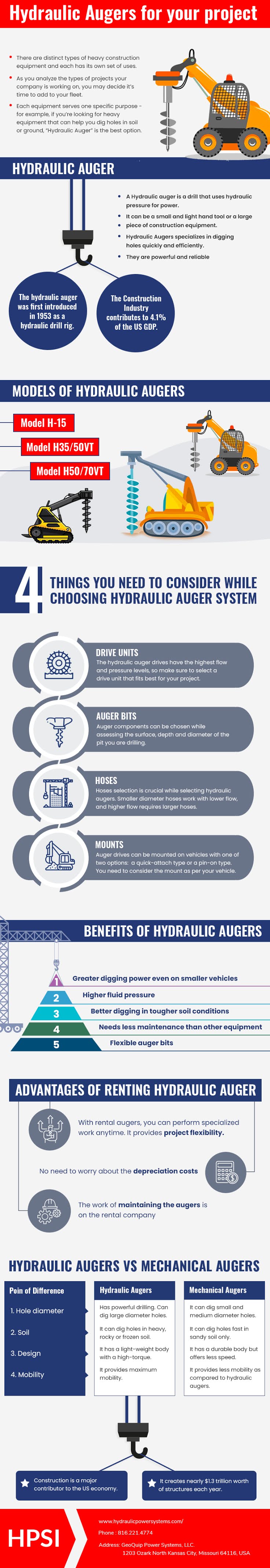

Hydraulic Augers

Vibratory Dampeners

Caisson Hammers

Sheeting Hammers

Excavator Mounted Hammers

Every pile driving equipment has its own specialty and identity. For instance, if you want to dig holes quickly, Hydraulic Augers are what you need. Thus, before choosing pile driving equipment you should consider a few important factors.

Factors to Consider

Following are the factors to be considered while selecting pile driving equipment for your project:

Soil Conditions

Rock soil, slit, and clay-based soils require different pile driving equipment. You should choose pile driving equipment after a thorough analysis.

Cost Parameters

Purchasing brand-new pile driving equipment can be expensive as compared to Pile Driving Equipment on Rentals in Missouri. If you need the equipment only for a single job, rental is preferred over buying it.

Which Pile Driving Equipment Should You Choose?

When you plan to start a construction project, you can choose pile-driving equipment as per its specifications and what work it does efficiently.

Vibratory Hammers

Vibratory Hammers can be used to drive piles with little or no noise in the residential area.

Caisson Hammers

Caisson Hammers are used for bridge pier foundations and dam construction. These hammers have superior vibration characteristics.

Sheeting Hammers

Sheetings Hammers are efficient in drinking piles into the silt, mud, or other types of environments.

Excavator Mounted Hammers

Excavator-mounted Hammers are compact and can be used in any kind of environment where the workspace is minimal in size.

Diesel Hammers

Diesel Hammers are used extensively to drive piles into the supporting soil layers.

Hydraulic Augers

Hydraulic Auger is a kind of drilling equipment that is used to dig holes with minimized downtime.

Vibratory Dampeners

Vibratory Dampeners are used to keep the pile driving equipment safe and to keep the energy focused where you want.

Pile Driving Equipment on Rentals in Missouri

Hydraulic Power systems offer Pile Driving Equipment on Rentals in Missouri. We are a global market leader in foundation construction equipment since 1980.

With our expertise and industry connections, we have access to the latest pile driving equipment that you require for your project. We take pride in the fact that we have a worldwide dealer network with numerous satisfied clients.